[Project Sharing] PLC control cabinet in communication networking mode!

How to simplify your diversified control cabinet?

In the field of industrial automation control, control cabinets play a vital role. It has important protection functions such as overload, short circuit, phase loss protection, etc., so it is very popular in many fields such as electric power, metallurgy, chemical industry, papermaking, environmental protection and sewage treatment. In response to this demand, we have launched a new type of comprehensive control cabinet, which uses in-cabinet Ethernet module integration. It has the characteristics of compact structure, stable operation, complete functions, etc., and can adapt to various large and small industrial automation control occasions.

Traditional control cabinet connection method

The traditional control cabinet consists of five parts: air switch, PLC, power supply, relay and terminal block. Among them, PLC is the core control unit, its input end is connected to the terminal strip, and its output end is connected to the intermediate relay. Generally speaking, the analog signal is connected to the terminal block through an isolation transmitter or directly, and is set appropriately according to the needs of the scene. In industrial-grade PLC control systems, common control combination methods include relay control + PLC control system, PLC single cabinet control system, PLC + touch screen control system, PLC + host computer control system, multiple PLC cabinet network control system, etc.

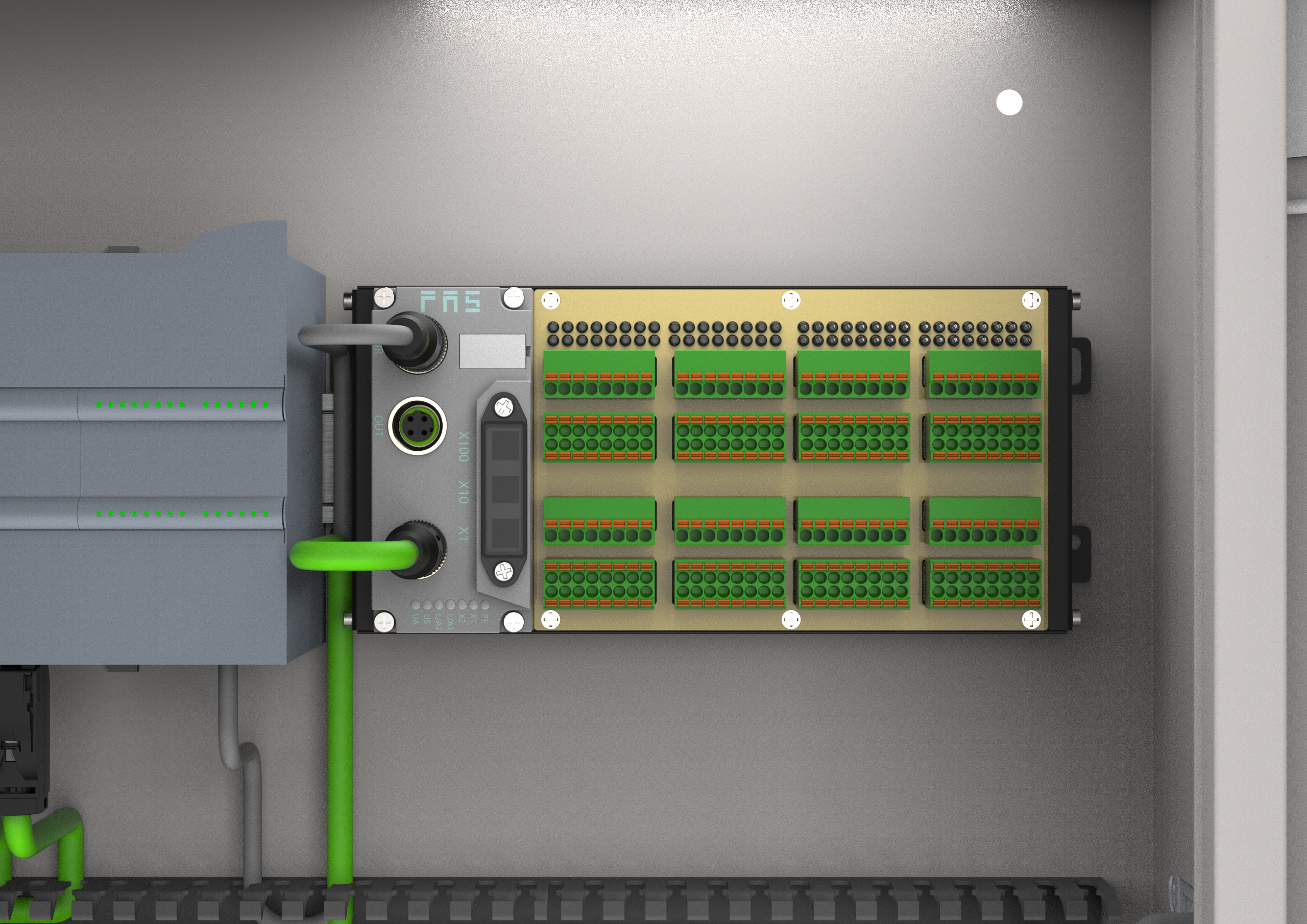

Recommended in-cabinet Ethernet control module

Communication networking mode (industrial Ethernet) is one of the more efficient solutions, with obvious advantages. In order to better meet customer needs, when we design and produce control cabinets: the core control unit uses PLC, all input terminals are connected to the in-cabinet Ethernet (digital, analog) module, and all output terminals are output to the intermediate Ethernet Relay module. Our Ethernet modules are perfectly compatible with many market PLC manufacturers and can meet the market's needs for various Ethernet communication modes, including support for Profinet, Ethernet/IP, EtherCAT, CC-Link IEF Basic, IO-Link and other protocols. In this mode, we can use the in-cabinet Ethernet module to achieve simple installation of the electric control cabinet, reduce the space occupation problem, and at the same time optimize the wiring system inside the control cabinet, effectively improving the efficiency of manual operation on site. Reduce operating time. One of the benefits of the communication networking mode is that it also has significant advantages in post-maintenance.

Diversified connection solutions are derived from actual application cases

In addition, in response to user needs in different fields, we have launched a broad and diversified product series, and can provide customers with professional customized products and efficient technical support services to help them stand out in the fierce market competition